So that the air or water flowing through the condenser will be very cold relative to the temperature of the discharge vapor, Why do we want the refrigerant to condense at this relatively high temperature? If the entering condenser water temperature is 85°, a water cooled system is designed so that the temperature of the refrigerant, right at the point where it first condenses, will be about 105°.

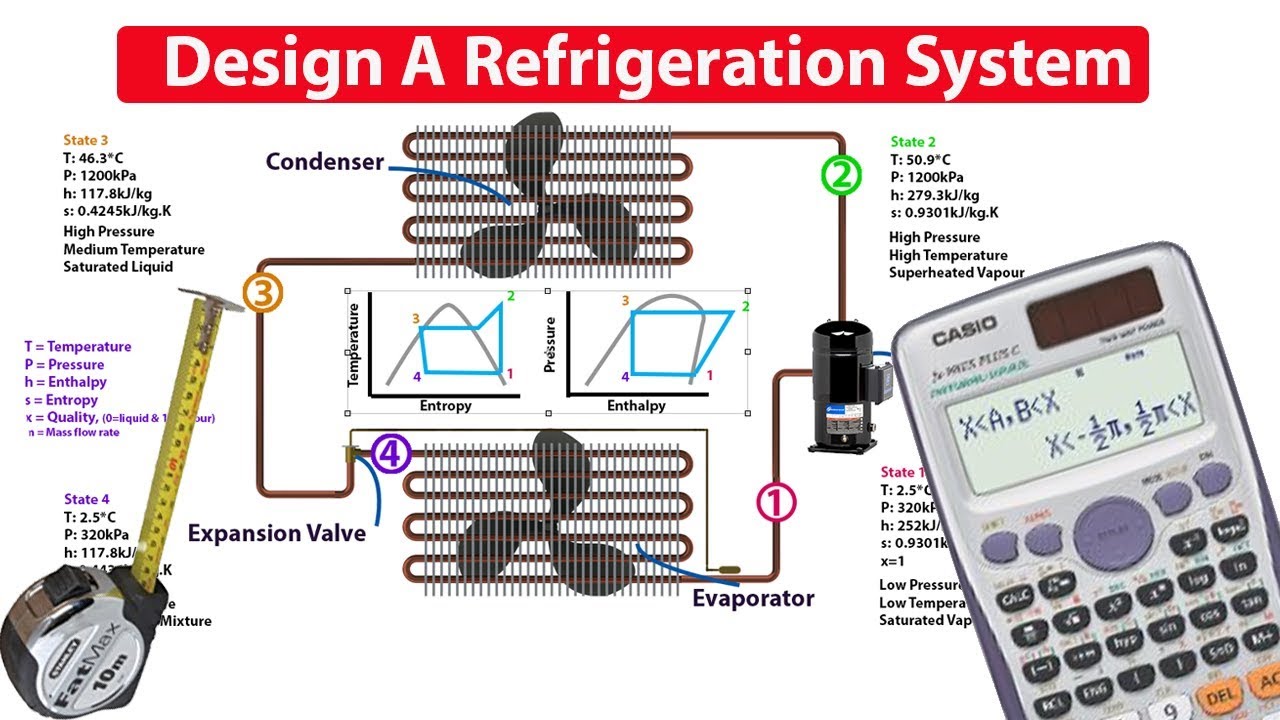

If the outside air temperature is 80°, an air cooled system is designed so that the temperature of the refrigerant, right at the point where it first condenses, will be about 105° to 115°. When the hot refrigerant vapor discharged from the compressor travels through the condenser, the cool air or water flowing through the condenser coil absorbs enough heat from the vapor to cause it to condense. With water cooled condensers, refrigerant should condense at a temperature about 10° above leaving condensing water temperature, or 20° above entering condenser water temperature. Most water cooled systems are designed for 75° to 95° entering condenser water temperature, with 85° being the design temperature. Most air cooled refrigeration systems are designed so that the refrigerant will condense at a temperature about 25 to 30 degrees above the ambient air temperature around the condenser. The solid red color represents high pressure liquid refrigerant. The red dots inside the piping represent discharge vapor. The rate of flow through the system will depend on the size of the unit,Īnd the operating pressures will depend on the refrigerant being used and the desired evaporator temperature.Ĭomponent #2 in this refrigeration cycle diagram is the condenser. The compressor is the heart of the system it keeps the refrigerant flowing through the system at specific rates of flow, and at specific pressures. It takes refrigerant vapor in from the low pressure side of the circuit, and discharges it at a much higher pressure into the high pressure side of the circuit.

#One stage cycles dx evaporator in coolpack free#

Because of the low specific volume of liquids, the pump work is relatively small and often neglected in thermodynamic calculations.We'll discuss the refrigeration cycle using this cycle diagram.įeel free to copy this refrigeration cycle diagram and print it out.

The pressure of the condensate is raised in the feed pump. In well designed and maintained condensers, the pressure of the vapor is well below atmospheric pressure, approaching the saturation pressure of the operating fluid at the cooling water temperature.ĥ-1 Isentropic Compression. The vapor-liquid mixture leaving the turbine (4) is condensed at low pressure, usually in a surface condenser using cooling water. Exit vapor qualities should be greater than 90%.Ĥ-5 Isobaric Heat Rejection. In practice, the expansion is limited by the temperature of the cooling medium and by the erosion of the turbine blades by liquid entrainment in the vapor stream as the process moves further into the two-phase region. The vapor is expanded in the turbine, thus producing work which may be converted to electricity. Further addition of energy causes evaporation of the liquid until it is fully converted to saturated steam (3).ģ-4 Isentropic Expansion. High pressure liquid enters the boiler from the feed pump (1) and is heated to the saturation temperature (2).

0 kommentar(er)

0 kommentar(er)